EN

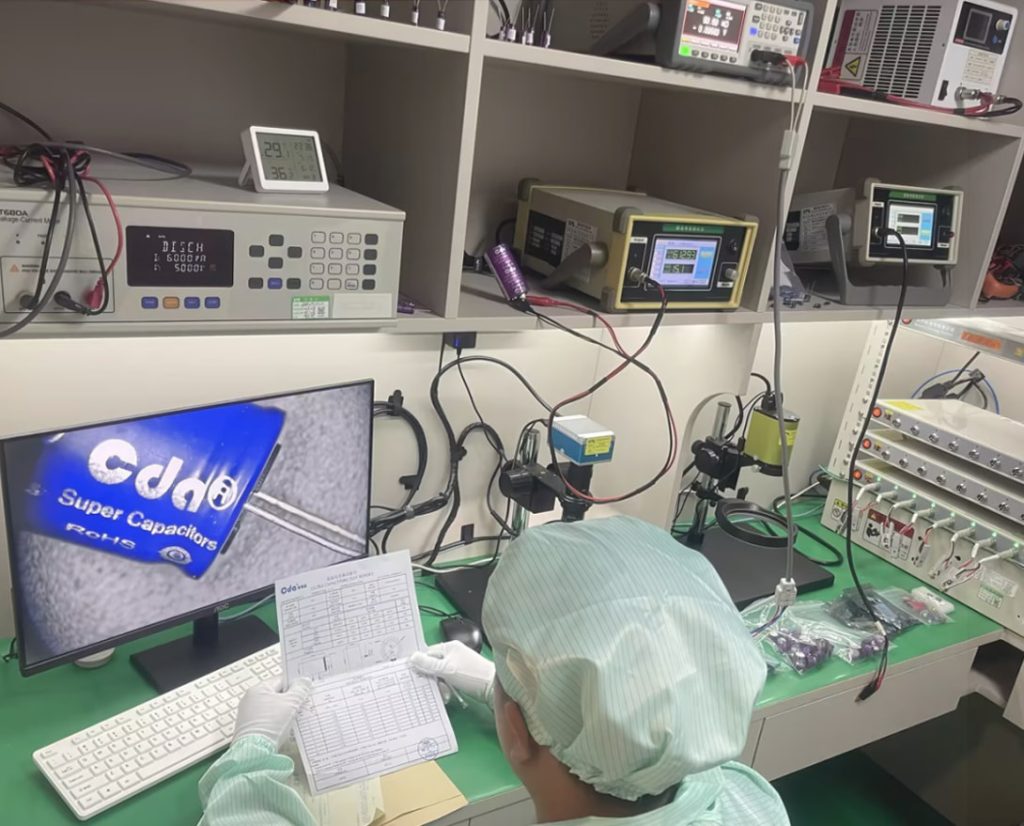

Quality

Warehouse

(QA Check)

1. Warehousing Management

- Receiving:Upon receiving goods from suppliers or other sources, conduct a preliminary inspection to verify quantity, quality, and specifications align with the order.

- Acceptance:Thoroughly inspect each item, log damaged or missing ones, and notify relevant personnel.

- Data Entry: Update the inventory management system to reflect new incoming items and their locations.

2. Inventory Management

- Inventory:Periodically, the system generates an inventory count list that lists the items and locations that need to be counted.

- Allocate:Warehouse location allocation is an important part of warehouse management, which involves the movement and re-layout of inventory, and the intelligent management of the system improves the efficiency of allocation.

- Early Warning:The intelligent inventory early warning system helps our company to respond to inventory changes in a timely manner and avoid the occurrence of too much or too little inventory.

3. Outbound Management

- Order Processing and pickingWhen the customer submits the order, the warehouse management system will immediately receive the order information and process it accordingly in time.

- Packing & Shipping:The system will record the outbound situation of each finished product in detail and generate the corresponding invoice.

All rights reserved© 2024 Shenzhen Kaifengda Technology Co., Ltd. All rights reserved

陈楚城Jason

QQ:2850974612

陈楚杰Jed

QQ:2850974615

何炎彬Ekko

QQ:2850974617

陈楚城Jason

TEL:15012886464

陈楚杰Jed

TEL:18824248778

何炎彬Ekko

TEL:13243784893

陈楚城Jason

ccc88@szkfd.com.cn

陈楚杰Jed

jed@szkfd.com.cn

何炎彬Ekko

ekko@szkfd.com.cn

陈楚洲Afu

陈楚杰Jed

何炎彬Ekko