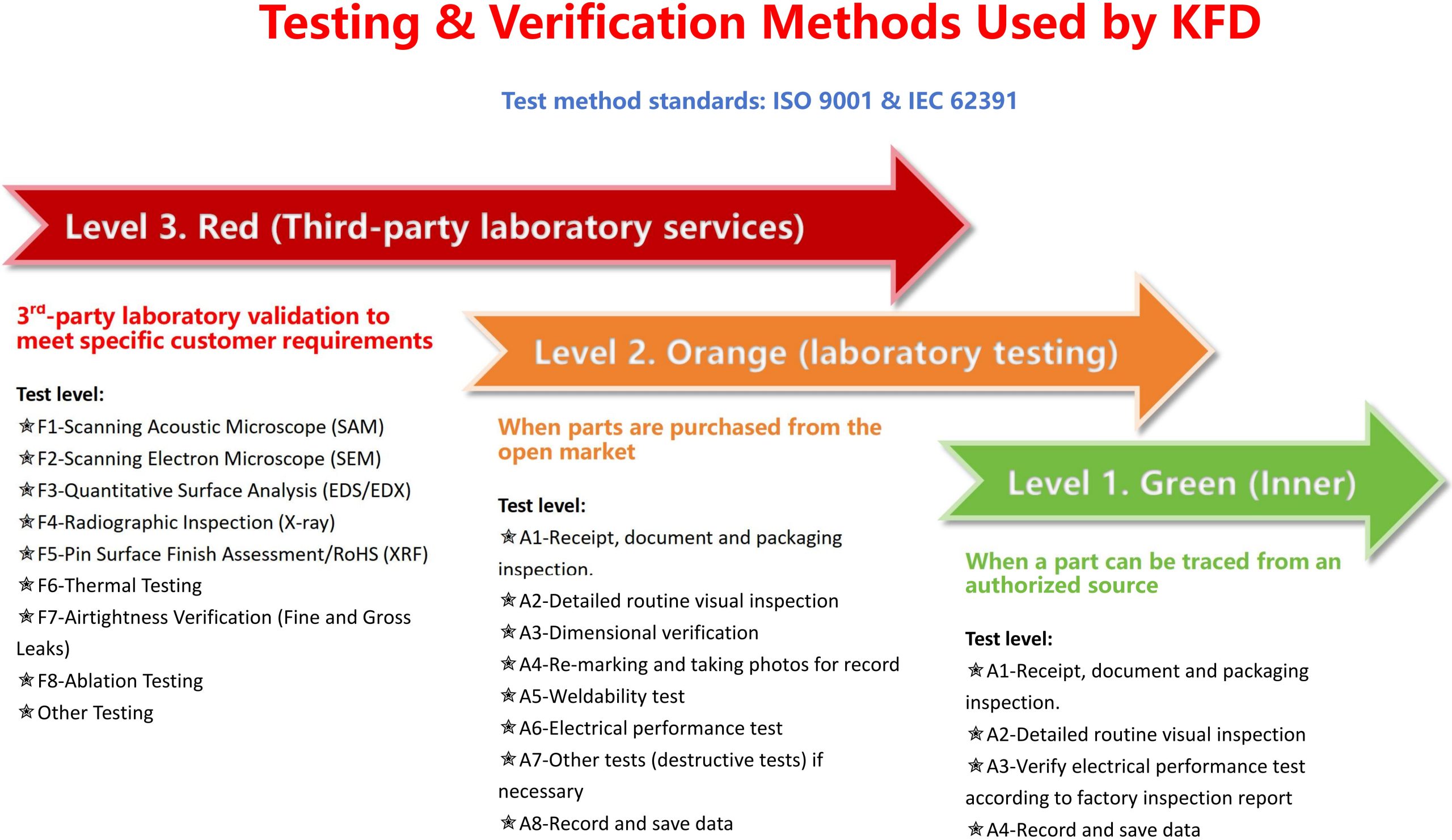

Quality

Quality Control Process

Level 1

QC Inspection Process

Packaging inspection

Check package condition forany sign ofdamage

Documents Verification

Verify the supplier's OQC report

Take a photo for record

Take photos of the received package (parts, labels, and packaging)

Requirement Verification

Verify whether the received parts are consistent with the PO.

Record and Receive

Record all the information and Photos onSystem and Internal Database

Storage Rack

The parts will be placed on the positioning rack for product warehousing.

Level 2

IEC standard inspection

PO/SO Requirement Verification

Verify whether the received information is consistent with PO and SO.

Parts Label Verification

Parts Label will beverified and comparedon Internal database

Perform Sampling Visual Inspection

Carry out sampling inspection (marking, leads, solder balls, surfaces and quantity)

Dimension Checking

The part dimensions will be measured according to the OQC report.

Take a photo for record

Take photos of the received package (parts, labels, and packaging)

Pin Surf. Treat. Eval. (XRF)

Surface and ScrapeTest will be performed

Solderability Test

Parts with over 2years Date code

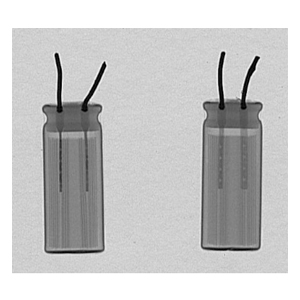

Radiographic Inspection (X-ray)

Verify Internal Component construction ( Non-destructive)

RoHS Lead Surface Eval.

Verify whether the pins comply with RoHS regulations

Electrical performance test

Verify the electrical performance reliability of parts

Record and Receive

Record all the information and Photos onSystem and Internal Database

Storage Rack

The parts will be placed on the positioning rack for product warehousing.

All rights reserved© 2024 Shenzhen Kaifengda Technology Co., Ltd. All rights reserved

陈楚城Jason

QQ:2850974612

陈楚杰Jed

QQ:2850974615

何炎彬Ekko

QQ:2850974617

陈楚城Jason

TEL:15012886464

陈楚杰Jed

TEL:18824248778

何炎彬Ekko

TEL:13243784893

陈楚城Jason

ccc88@szkfd.com.cn

陈楚杰Jed

jed@szkfd.com.cn

何炎彬Ekko

ekko@szkfd.com.cn

陈楚洲Afu

陈楚杰Jed

何炎彬Ekko